Gear Cutting

Integrated Components understands the pressures of working with OEM companies – it can be stressful and push your company to the limit. If you have contracts that are too big and you need help, we are there for you with our gear cutting services. Gears are sometimes a forgotten part of engineering and planning, and it usually pays to contract out – it saves you time!

Our gear cutting services extend to everything from dragsters, structural components on business jets, to the flight control on the new Textron Scorpion jet.

Deadlines are important, but so is quality work that you can stand behind. That’s why we’ve become a trusted name in Wichita and beyond – our skills and experience are backed by a commitment to provide quality work you can trust. When your name is on the line, you want to work with a company with proven results.

FAQs

What size gears do you work with?

We put teeth on gears from 5/16 up to 10 inches in diameter.

Do you specialize in manufacturing a particular type of gear?

Our expertise spans a wide variety of gear types including spur gears, serrations, involute splines, as well as internal and external gears.

What type of materials can teeth be added to?

Essentially any type of material found on an aircraft. Aluminum, nylatron, hardened stainless steel, and titanium are the types we work with most.

What is your lead time?

Our lead time to cut gear teeth starts at 3 weeks.

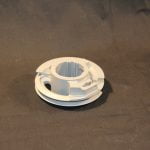

Gallery

Videos

Integrated Components Inc. is a premiere manufacturing facility located in Wichita, Kansas with customers from across the continent.

With nearly 20 years of proven quality work, you can count on us to deliver high quality gear cutting, part manufacturing, and assembly.

We serve various industries which include aircraft, defense, racing, printing and recreation. Contact us today to learn how we can deliver the exact precision and quantity you need.

Tell Us About Your Project

If it has to do with gears, you are in the right place.